Building a Unified Asset Intelligence Ecosystem

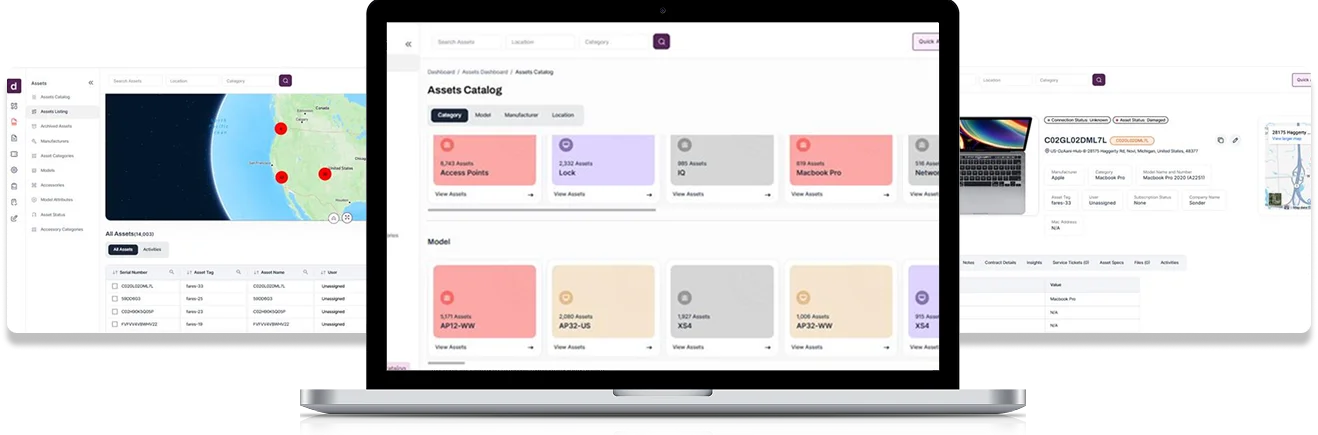

In a world where operational efficiency depends on real-time visibility, Dalos envisioned a platform that could offer complete control over physical and digital assets. With industries like logistics, construction, and hospitality becoming increasingly reliant on smart infrastructure, the need for a scalable, predictive, and intuitive platform was clear.

Turning Complexity into Control: Our Platform Strategy

- Modular Architecture for Scalability.

- Predictive Maintenance at the Core.

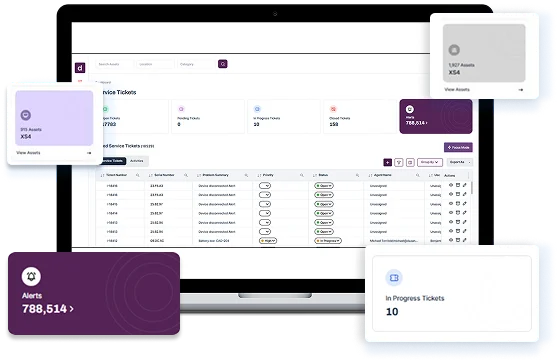

- Integrated Managed Services with Remote Support Tools for Continuous Performance.

The project began with deep discovery sessions to understand Dalos' diverse industry use cases and infrastructure touchpoints. From heavy construction machinery to fleet sensors and smart building systems, we mapped out the full lifecycle of asset behavior and stakeholder workflows.

Our goal was to deliver a cloud-native, modular system capable of real-time data ingestion and intelligent processing. Codelogicx implemented a microservices-based architecture with scalable APIs for seamless integration with ERP, CRM, SAP, and third-party fleet management systems.

To ensure long-term success, we also built modules to support Dalos' 24/7 live support desk, equipping teams to remotely monitor assets, escalate issues, and resolve incidents in real time.